How To Choose The Right Type Of Mounting For Your Hardware

Even the strongest, most durable hinge or latch may fail if it’s attached to your design with an improper mount. Determining how your hardware should be fastened to your enclosure is a crucial decision, and choosing the wrong type of mount can lead to expensive repairs and replacements.

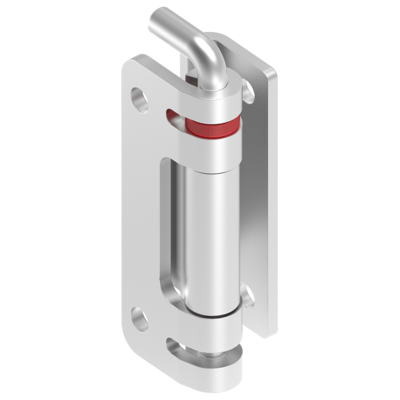

Some articles, such as EMKA’s new 135° hinge with captive pin and 120° hinge (program 1031), offer both weld-on and screw-on mounting options, and choosing which one is right for your design requires careful consideration of factors such as:

- Cost

- Convenience

- Permanence

- External environment

135° hinge with captive pin and 120° hinge

EMKA also supplies a variety of clip-on products, which can offer a further range of benefits that can add extra value to some designs.

Here are what three common types of mounting can do for your enclosure:

Weld-On

Weld-on mounts are ideal for hardware that needs to stay put at all costs. They’re far more difficult to remove than screw-on or clip-on mounts, but that’s what makes them a great option for hardware that needs to be permanently attached to an enclosure.

A weld-on mount may be an optimal solution for your design if your hardware needs to resist:

- Moisture – Gaps between moving parts in other mounts may leave room for precipitation or condensation, which can freeze or cause corrosion that can make your design fail.

- Impact – Enclosures that are frequently subjected to slamming or collisions may see screws or other removable hardware jarred out of place, risking misalignment or complete breakage.

- Time – If your hardware is unlikely to ever need replacement, a weld-on mount can provide adequate support for heavy attachments that can wear on your enclosure as the years pass.

This heavy-duty mount can protect crucial parts of your design from failure even under extreme duress.

Screw-On

Choosing a screw-on mount for your hardware can facilitate the application and removal process while still providing a secure hold for your design. Screw-on hardware offers the support of industrial metal without the commitment of a weld, offering an easy removal option if the hardware or an attached part of your design is damaged or worn and needs to be replaced.

Screw-on mounts are often an economic choice as well. The tools and time involved in the initial installation of screw-on hardware are often significantly less than that involved for weld-on mounts. Additionally, if a part needs to be replaced or repaired, a screw-on mount allows it to be detached and sent separately rather than requiring the hassle (and costs) of transporting the entire unit.

Clip-On

When easy application and removal is a top priority, clip-on mounts may be the perfect solution for your design. This mount is becoming more common (and more popular) for hardware such as quarter-turns, and some of our newest products, such as the quarter turn for quick mounting (program 1000) feature this type of application.

Quarter turn for quick mounting

While they may not offer the same extreme level of security as a weld-on mount, high-quality clip-on hardware is still reliable, especially when made of corrosion-resistant material such as stainless steel and high-performance plastic. EMKA’s clip-on products can also cut assembly time by up to 80 percent, and because many don’t require extra tools, they can also help reduce costs.

A Mount That Holds Weight

Whether your priority is strength, convenience, or something in the middle, you can find the perfect mount for your design’s hardware. Weld-on, screw-on, and clip-on mounts are all reliable as long as they’re well made and properly installed, but choosing the perfect option for your container requires careful consideration of your enclosure’s unique environment and design.

Contact us today to learn more about how to choose the right mount type for your enclosure.